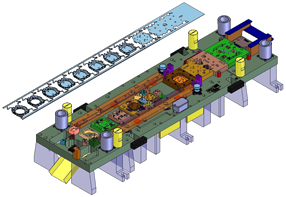

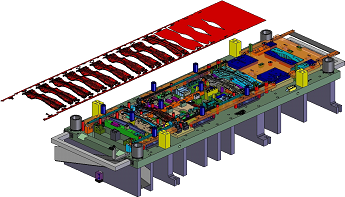

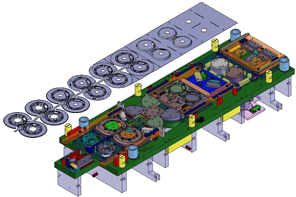

Progressive Dies

STM has designed and built hundreds of progressive dies for parts requiring tight tolerances, high strength material, stainless steel and aluminum.

With our vast experience in die design and build we excel when working with complex forms, curling, hemming, drawn parts, extrusions, in-die tapping, in-die nut or stud installation (bowl feed or reel feed).

STM designs and builds tools to fit the desired press application and targeted strokes per minute, at all times insuring consistent part quality to keep our customers press time profitable.

Our progressive and transfer die experience includes: diaphragm plates, booster shells, cross members, exhaust components, airbag components, seat components, frame components, suspension components, hitch and bumper components, pillar components, roll form pre-pierce tooling, transfer bars / arms and fingers - high strength, stainless, and aluminum materials.

We focus on providing our customer's with the highest quality tooling, meeting close tolerances and stringent die specifications. With tryout capabilities up to 2000 tons accommodating dies up to 84" wide x 228" long.

Click thumbnails below to enlarge.